How to find a new idea for the sustainable and sound development of enterprises, optimize and improve the overall structural efficiency of enterprises, reduce costs, improve quality and increase efficiency, is the core goal that every enterprise helmsman has been thinking about and pursuing.

The development of industrial robots has promoted the pace of digital production transformation of enterprises. The rationality of logistics planning is one of the important factors for the long-term effective development of factories, and AGV is not only a simple material handler in the intelligent manufacturing production line, but also a capable assistant in the assembly line. In addition to being responsible for the round trip of the corresponding materials to and from the side of the production line and the corresponding warehouse, it can also provide flexible assembly production according to the customer's assembly line needs and realize the function of "intelligent and efficient + man-machine friendly interaction".

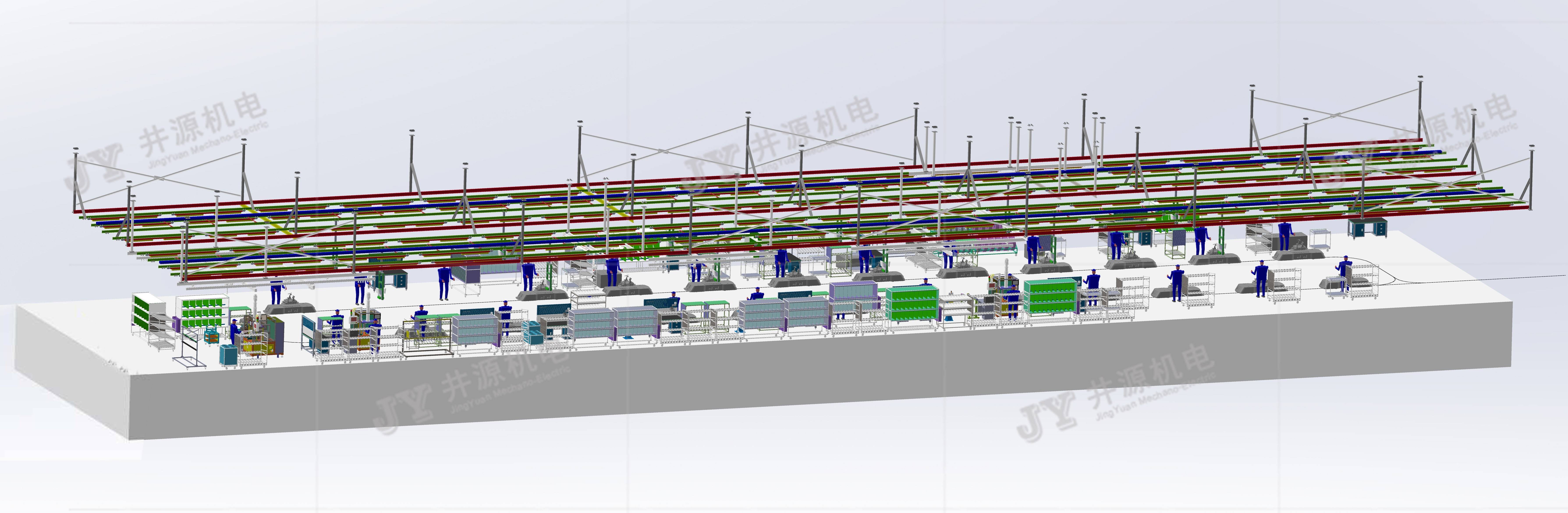

Traditional assembly line(Image source: Internet)

The traditional motorcycle industry assembly line is mainly based on the plate and chain assembly line, which mainly uses the chain plate surface as the bearing to realize the smooth transportation of products, but it is not very friendly in the face of the mixed line production of multiple types of machines, which is not suitable for the current enterprise factory seeking automation upgrade requirements. The assembly type AGV can be well integrated with the current intelligent production needs, easy construction, easy for customers to follow the expansion, transformation needs, the use of intelligent AGV, improve the overall production and assembly efficiency of enterprises, its assembly form more flexible, can meet the personnel of different heights and operating habits, lift adjustment, improve the convenience of personnel operations, at the same time, the MES management system can real-time monitoring, collection At the same time, the MES management system can monitor, collect and feedback the operation of tightening and other processes in the production process in real time, and complete the collection of data and information. Compared with the traditional plate and chain assembly line, the AGV assembly line is more intelligent. In the face of equipment failure problems encountered during the production process, the AGV can be directly taken off the line from the faulty station, and then put back on the line from the faulty station after solving the problem, without affecting the overall operation process of the production line.

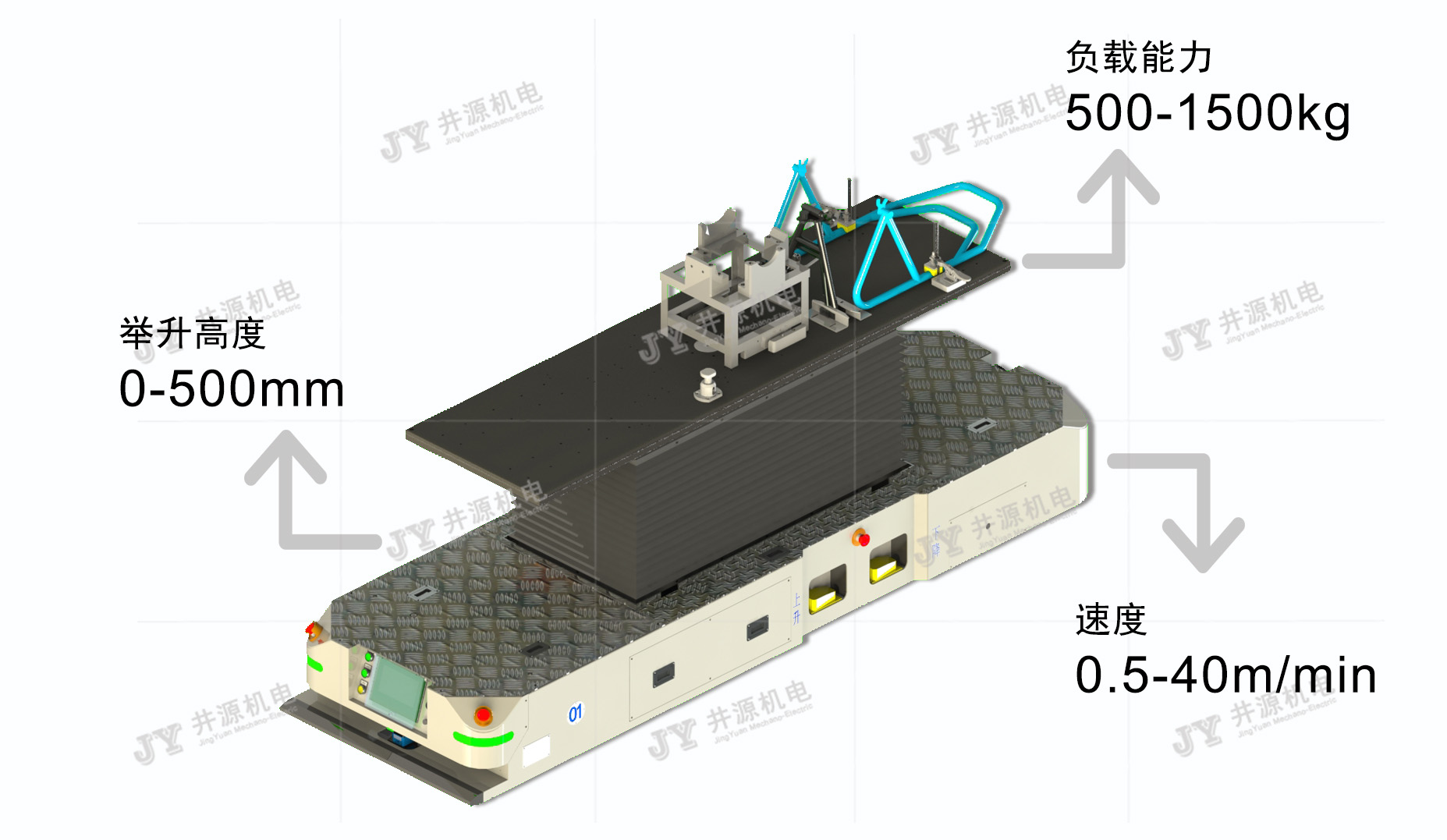

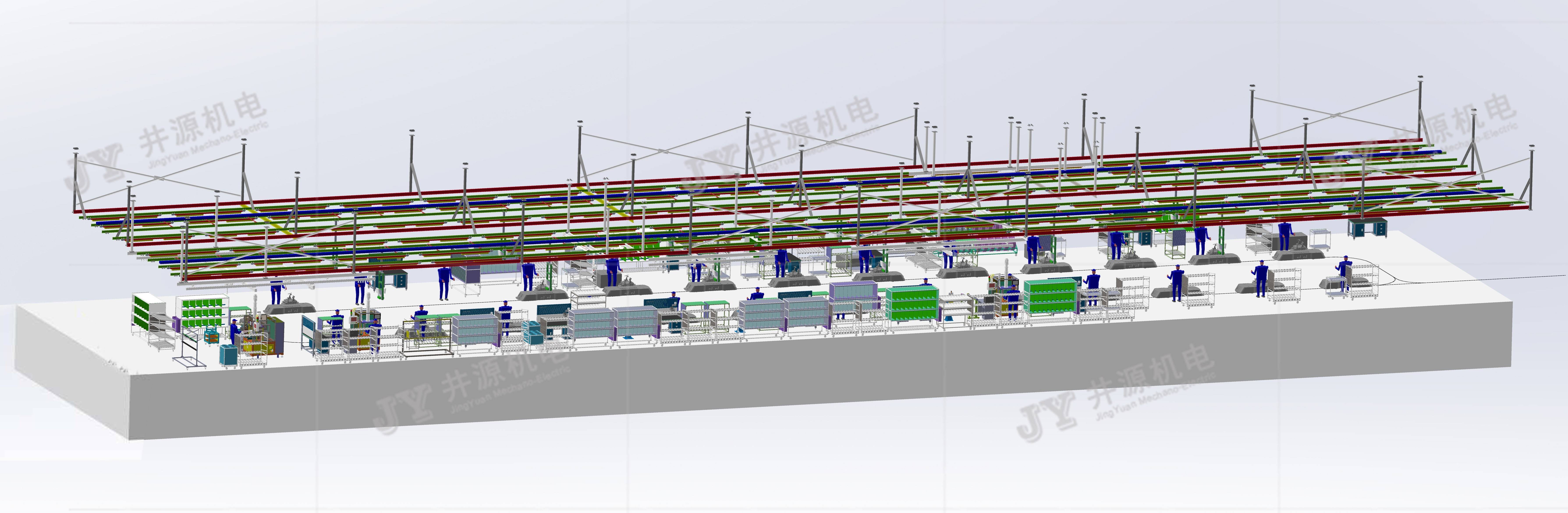

Intelligent AGV assembly line

Well source assembly type AGV

Assembly type AGV features.

◆Can stop at any position within the lifting height range to adapt to the assembly operation of different models, different work stations and different heights.

◆Replace traditional plate chain assembly line and roller assembly line, low speed operation mode can be benchmarked against traditional chain plate line under low beat cycle production.

◆Flexible assembly production, save labor cost, improve production efficiency, and meet the demand of intelligent transformation and upgrading transformation of enterprises.

In addition to assembly type AGVs, latent traction type AGVs also play a vital role in motorcycle production lines. It is responsible for the distribution of SPS materials to the production assembly line from the assembly island (pre-assembly area) on the side of the production line, to realize the linkage of SPS material carts and main line assembly AGVs. The use of AGVs makes the transfer of various materials orderly, and also reduces the labor intensity of operators, effectively promoting the production efficiency and assembly quality of enterprises.

Wellspring latent traction AGVs

Up to now, Inoac has invested more than 1330 AGVs in the motorcycle industry, realizing multi-brand and multi-machine flexible assembly production in the motorcycle industry, and creating the first motorcycle whole-line AGV bearing assembly case for customers in China, and in the future, Inoac will continue to provide more professional intelligent manufacturing solutions for the intelligent transformation and upgrading of the industry. Please continue to pay attention to and choose well source electromechanical, together with each other to witness the two-way growth.